Intro

Bitumen 120/150, also known as penetration grade bitumen, is a crucial material used extensively in the construction and maintenance of roadways. It is classified based on its penetration value, which indicates the hardness or softness of the bitumen. The numbers 120/150 refer to the penetration range, measured in tenths of a millimeter, representing a moderate hardness level suitable for various climatic conditions. This grade of bitumen is particularly favored in regions with moderate temperatures, offering a balanced performance in terms of durability and flexibility.

Bitumen 120/150 Description

In general, Bitumen 120/150 is used as a Paving Grade Bitumen suitable for road construction and for the production of asphalt pavements with superior properties, especially in road and airport constructions and other similar applications. It is a standard Penetration Grade of Bitumen according to ASTM D946M. Hot mix asphalt for bases and wearing courses is mostly made using this grade of bitumen. Vacuum residue is used to make Penetration Grades of Bitumen, which is then heated and blown by hot air in the Blowing Unit. The completely automated process produces a consistent, homogenous end product.

Bitumen Penetration Grade 120/150 is a type of bitumen that is created when the vacuum bottom (the feedstock for making bitumen that is derived from distillation tower residue in vacuum oil refineries) is oxidized at the bitumen production unit in such a way that its penetration point (a type of test to determine the hardness of bitumen) becomes between 120 and 150. Bitumen 120/150 is compatible with all types of aggregates and has a high flash point and good adhesion capabilities.

History of Bitumen 85/100

This substance was employed as an anti-humidity compound, to preserve wood, and for a variety of other applications, including embalming, sculpting, and decorating.

In 1712 A.D., natural Bitumen stones were found in France, marking the birth of the current Bitumen business. Historically, bituminous materials were simply deposited in lumps on the surface of local roads and left to be progressively worn down and compacted by traffic. This approach was highly effective, and in a short amount of time, advancements in this sector were developed, such as powdering and heating the material before to usage.

Bitumen 120/150 product

The production of 120/150 bitumen involves the refining of crude oil through a process called fractional distillation. During this process, crude oil is heated and separated into various fractions based on their boiling points. Bitumen is obtained from the heaviest fraction of crude oil, which is then further processed to meet the desired specifications.

To produce penetration bitumen 120/150, the bitumen is subjected to a series of tests to determine its penetration value, which indicates the hardness of the material. The penetration value refers to the depth in tenths of a millimeter to which a standard needle penetrates the bitumen sample under specified conditions of time, temperature, and applied load. 120/150 Asphalt Cement has a penetration value ranging between 120 and 150 Deci millimeters, hence its denomination.

The Capability of Oxidized Bitumen Grade

Bitumen 120/150 Uses

Asphalt Penetration Grade 120/150 is appropriate for asphalt pavements with outstanding qualities and for building roads. Hot mix asphalt for bases and wearing courses is made with this kind of bitumen.

- Road Construction: Bitumen 120/150 is widely used in road construction as a binder in asphalt mixes. It provides the necessary cohesion and flexibility to the asphalt, contributing to the durability and stability of road surfaces.

- Asphalt Emulsions: This type of bitumen can be used to produce asphalt emulsions. Asphalt emulsions are water-based bitumen dispersions employed for road maintenance activities, such as chip seals, surface treatments, and tack coats.

- Roofing: Bitumen 120/150 is utilized in the roofing industry for manufacturing roofing felt, shingles, and other roofing materials. Bitumen-based roofing materials offer waterproofing and weatherproofing properties.

- Waterproofing: The waterproofing industry uses Bitumen 120/150 for waterproofing applications, including the treatment of foundations, basements, and other structures. It forms a durable and impermeable layer, preventing water ingress.

- Pipe Coating: In the oil and gas sector, Bitumen 120/150 is applied as a coating for pipes to provide corrosion resistance and insulation. This protective coating helps safeguard pipelines from environmental factors.

- Pavement Sealants: Bitumen 120/150 can be used in pavement sealants applied to existing asphalt surfaces. These sealants enhance the longevity of pavements and protect against weathering and aging.

- Adhesives and Binders: Bitumen 120/150 serves as a crucial component in the production of adhesives and binders. It imparts bonding strength and acts as a binding agent in various industrial applications.

- Soundproofing: Bitumen 120/150 is employed in the manufacturing of soundproofing materials for buildings and infrastructure. Its ability to absorb sound contributes to reducing noise transmission.

- Construction Mastics: Bitumen 120/150 may be used in construction mastics, which are flexible, adhesive compounds applied to seal joints and cracks in construction projects.

The specific use of Bitumen 120/150 can vary based on regional specifications, climate conditions, and project requirements. It is important to consider the penetration value, which influences the bitumen’s hardness and consistency, affecting its suitability for different applications.

Bitumen 120/150 Advantages

- Durability: It is resistant to deformation and fatigue, contributing to the longevity of road pavements.

- Weather Resistance: Its ability to withstand temperature fluctuations, moisture, and UV exposure makes it suitable for use in diverse climatic conditions.

- Smooth Surfaces: Asphalt 120/150 helps create smooth and skid-resistant road surfaces, enhancing safety for motorists.

- Cost-Effectiveness: The long service life and low maintenance requirements of roads constructed with Bitumen 120/150 contribute to cost-effectiveness over time.

Packing

Bitumen 120/150 is commonly packed in new steel drums, 150, 180 & 220 Kg barrels and Jumbo Bags or Bitubag and 10 & 20kg Tubular cartons. The packing of bitumen 120/150 can vary depending on the manufacturer and supplier. It is typically packed in drums or barrels made of steel or plastic. The drums are usually sealed tightly to prevent any leakage or contamination. The size of the drums can vary, but common sizes include 180 kg, 200 kg, and 220 kg. Some suppliers may also offer bulk packaging options such as tanker trucks or containers for larger quantities of bitumen. also, bitumen 120/150 has more than packing, we will explain in the following:

Kind of Packing for Bitumen 120/150

The Bitumen 85/100 is packed in Different Major:

- Jumbo Bag

- Steel Drums

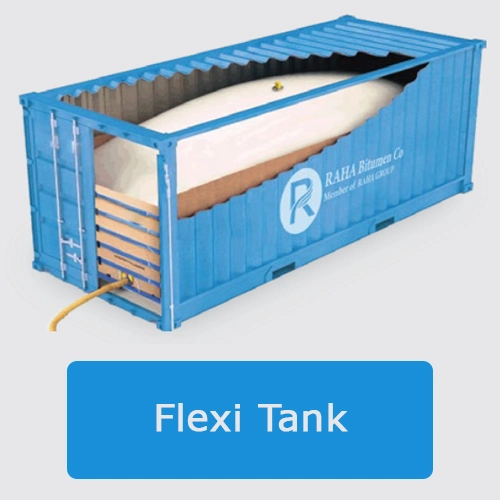

- Flexi Tanks

- Bulk in Trunk Tunker

- Bulk in Bulk Vessel

- Bulk in Bitutainer

1. Jumbo Bag

Jumbo bags, also known as Flexible Intermediate Bulk Containers (FIBCs) or big bags, are a popular choice for transporting Bitumen 120/150. These large, flexible bags are typically made from woven polypropylene and are designed to hold between 500 to 2,000 kg of bitumen.

Handling:

- 1MT Jumbo Bag with Pallet and Steel

Cage:

Loading 20Ton in 20ft Container = 20Ton Net

- 1MT Jumbo Bag without Pallet and Steel

Cage:

Loading 20Ton in 40ft Container = 20Ton Net

Advantages of Jumbo Bags in Bitumen 120/150:

- Cost-effective for bulk transportation

- Easy to handle with forklifts or cranes

- Stackable, maximizing storage space

- Reduced risk of contamination

- Suitable for both solid and semi-solid bitumen forms

2. Steel Drums

- 180kg New Steel Drum :

Loading 110 Drum in 20ft Container= 19.80 Ton Net - 150kg New Steel Drum:

Loading 110Drum in 20ft Container= 16.50 Ton Net

Advantages of Steel Drums in Bitumen 120/150:

- Excellent protection against external elements

- Easy to handle and stack

- Suitable for smaller quantity orders

- Reusable or recyclable

- deal for long-term storage

3. Flexi Tanks

Flexi tanks, also known as flexibags or flexitanks, are large, flexible containers designed to fit inside standard 20-foot or 40-foot shipping containers. They are an excellent option for transporting large quantities of liquid or semi-liquid Bitumen 85/100.

Advantages of Flexi Tanks in Bitumen 120/150:

- High capacity (up to 24,000 liters in a 20-foot container)Cost-effective for bulk liquid transportation

- Eliminates the need for drum handling and cleaning

- Maximizes the use of container space

- Reduces packaging waste

4. Bulk in Truck Tanker

- Loading 24-25Ton in Bulk Tanker

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

Specification

| Bitumen 120/150 | Test method | Unit | Specification |

|---|---|---|---|

| Specific gravity @ 25°C | ASTM D70 | Kg/m3 | 1000-1050 |

| Penetration @ 25°C | ASTM D5 | mm/10 | 120/150 |

| Softening point °C | ASTM D36 | °C | 38 min |

| Ductility @25 °C | ASTM D113 | Cm | 100 min |

| Loss on heating(wt.) % | ASTM D6 | wt. % | 0.5 max |

| Drop in penetration after heating % | ASTM D5-D6 | % | 20 max |

| Flashpoint °C | ASTM D92 | °C | 218 min |

| Solubility in Trichloroethylene | ASTM D2042 | wt. % | 99 min |

| Spot test | – | Negative |

In Summary

Bitumen 120/150, also known as penetration grade bitumen, is a vital material used extensively in road construction and maintenance. Its classification is based on the penetration value, which measures the bitumen’s hardness or softness in tenths of a millimeter, with 120/150 indicating a moderate hardness level suitable for a variety of climates. This grade of bitumen is particularly effective in regions with moderate temperatures, offering a balance of durability and flexibility, and is commonly used in paving applications such as roadways and airport runways. Its production involves refining crude oil through fractional distillation and further processing to achieve the desired penetration grade.

Bitumen 120/150’s versatility extends beyond road construction to applications in roofing, waterproofing, pipe coating, and soundproofing. It is also used in producing asphalt emulsions for road maintenance and pavement sealants to enhance the longevity of asphalt surfaces. Its high flash point, good adhesion capabilities, and compatibility with all types of aggregates make it a reliable choice for various industrial uses. Packing options for Bitumen 120/150 include steel drums, jumbo bags, flexi tanks, and bulk transportation methods, ensuring efficient and contamination-free delivery to different project sites.