Intro

Bitumen 160/220, or penetration grade bitumen, is vital in the construction and road-building industries. This versatile petroleum-based product is characterized by its specific penetration range of 160 to 220 decimillimeters, as measured by standard testing methods. Derived from the heavy residues of crude oil distillation, bitumen 160/220 offers a balance of durability and flexibility that makes it particularly suitable for various applications in regions with moderate climates. Its unique properties, including adhesiveness, water resistance, and thermal stability, contribute to its widespread use in asphalt mixtures for road surfacing, waterproofing membranes, and other construction materials. As infrastructure development continues to be a priority worldwide, understanding the characteristics and applications of bitumen 160/220 becomes increasingly important for engineers, contractors, and industry professionals.

General Description of Bitumen 160/220

In road construction, Bitumen 160/220 is commonly used in asphalt mixtures for surfacing. Its softer consistency allows for better workability during application, while still providing a durable surface capable of withstanding moderate traffic loads. The grade’s temperature sensitivity makes it well-suited for areas that do not experience extreme temperature fluctuations, as it maintains its performance characteristics within a moderate range.

The versatility of Bitumen 160/220 can be further enhanced through modification. By adding polymers or other additives, specific properties of the bitumen can be altered to meet particular project requirements. This adaptability, combined with its balanced set of properties, makes Bitumen 100/150 a valuable material in the construction industry, capable of meeting a wide range of needs in moderate climate conditions.

Process of Bitumen 100/150 Grade

-

Crude Oil Distillation:

- The process begins with the atmospheric distillation of crude oil.

- Lighter fractions are separated, leaving behind a residue.

-

Vacuum Distillation:

- The residue from atmospheric distillation undergoes vacuum distillation.

- This process further separates heavier components, producing vacuum residue.

-

Air Blowing (if necessary):

- If the vacuum residue doesn’t meet the required specifications, it may undergo air blowing.

- This process involves injecting air into the heated bitumen to adjust its properties.

-

Blending:

- Different bitumen streams may be blended to achieve the desired penetration range of 160/220

- Softer and harder grades might be mixed to reach the target consistency.

-

Cooling:

- The bitumen is cooled to a temperature suitable for storage and transportation.

-

Quality Control:

- Rigorous testing is performed to ensure the bitumen meets the 160/220 grade specifications.

- Tests include penetration, softening point, and other relevant properties.

-

Storage:

- The finished product is stored in heated tanks to maintain its liquid state.

-

Packaging/Distribution:

- Bitumen 160/220 is either loaded into tankers for bulk transportation or packaged in drums or bags for smaller quantities.

Properties of Bitumen penetration 160/220

The Capability of Bitumen 160/220

Bitumen 160/220 boasts a range of capabilities that make it a versatile and reliable material in the construction industry. Its penetration value, which falls between 160 and 220 millimeters, indicates a medium-hard consistency, balancing flexibility and durability. This specific grade of bitumen is particularly suited for applications that demand resilience under moderate to heavy traffic conditions.

Bitumen 160/220 Applications

Bitumen 160/220 finds its primary application in road construction and maintenance. Its moderate softness makes it ideal for creating asphalt pavements for highways, streets, and parking lots, particularly in regions with temperate climates. It is commonly used in base and binder courses of road layering, providing a durable foundation for the surface course. Additionally, this grade of bitumen is effective for surface dressing operations, helping to extend the lifespan of existing roads by sealing and protecting them from water ingress and surface wear.

In the construction industry, Bitumen 160/220 plays a crucial role in waterproofing applications. It is extensively used in the production of roofing membranes, offering excellent protection against water infiltration for both residential and commercial buildings. The material’s water-resistant properties also make it valuable for waterproofing bridge decks, underground structures, and foundations. In large-scale projects, it is utilized for dam and reservoir lining, ensuring the integrity of these critical infrastructures.

2. Steel Drums

- 180kg New Steel Drum :

Loading 110 Drum in 20ft Container= 19.80 Ton Net - 150kg New Steel Drum:

Loading 110Drum in 20ft Container= 16.50 Ton Net

Advantages of Steel Drums in Bitumen 100/150 :

- Excellent protection against external elements

- Easy to handle and stack

- Suitable for smaller quantity orders

- Reusable or recyclable

- deal for long-term storage

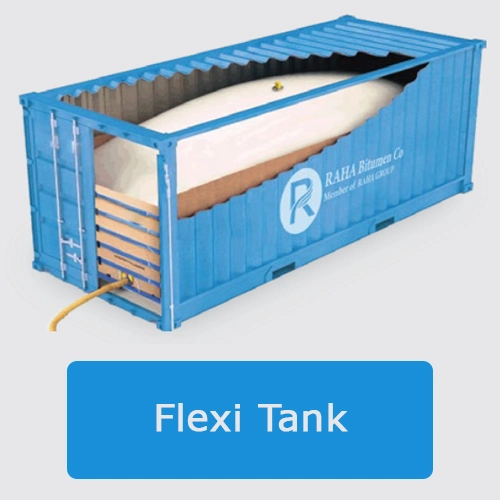

3. Flexi Tanks

Flexi tanks, also known as flexibags or flexitanks, are large, flexible containers designed to fit inside standard 20-foot or 40-foot shipping containers. They are an excellent option for transporting large quantities of liquid or semi-liquid Bitumen 100/150 .

Advantages of Flexi Tanks in Bitumen 100/150 :

- High capacity (up to 24,000 liters in a 20-foot container)Cost-effective for bulk liquid transportation

- Eliminates the need for drum handling and cleaning

- Maximizes the use of container space

- Reduces packaging waste

4. Bulk in Truck Tanker

- Loading 24-25Ton in Bulk Tanker

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

Specification

| Bitumen 160/220 | Test method | Unit | Specification |

|---|---|---|---|

| Penetration @ 25°c | IP 49 | mm | 160/220 |

| Softening point °c | IP 58 | °C | 35/43 |

| Kinematic Viscosity @ 135 °C | IP 370 | mm2/s | 135 min |

| Flashpoint °c | IP 36 | °C | 220 min |

| Solubility is CS2(wt) % | IP 47 | wt % | 99 min |