Export of Bitumen 70/100 to China Destinations

Export of Bitumen 70/100 to China Destinations

Intro

Bitumen 70/100 is a versatile and widely used type of bitumen, often referred to as asphalt binder, renowned for its balance of flexibility and durability. It falls within the penetration grade bitumens, classified based on the depth (measured in tenths of a millimeter) a standard needle penetrates the bitumen sample under specific conditions. The 70/100 designation signifies that the needle penetrates between 70 and 100 units, indicating a medium-hard consistency. This makes Bitumen 70/100 particularly suitable for a range of climatic conditions and various types of road construction and maintenance.

Bitumen 70/100 is also appreciated for its workability during the construction process. Its medium penetration grade ensures that it can be easily mixed and applied, while still providing a strong, cohesive bond once it sets. This makes it a favorite among contractors and engineers who seek efficiency and reliability in their paving materials. Additionally, the bitumen can be modified with polymers or other additives to enhance certain properties, such as elasticity or resistance to deformation, further broadening its application scope.

General Description of Bitumen 70/100

Bitumen 70/100, also known as penetration-grade bitumen, is a widely used construction material known for its versatility and durability. It is a type of bitumen that falls within a specific range of penetration values, indicating its consistency and softness. Bitumen 70/100 has a penetration value of 70 to 100 dmm (0.1 mm) at 25 degrees Celsius, which makes it suitable for a variety of applications in road construction, waterproofing, and industrial processes.

One of the key characteristics of Bitumen 70/100 is its excellent adhesive properties, which allow it to effectively bind various aggregates together to form durable asphalt mixtures. This makes it an ideal choice for use in asphalt pavements, where it helps enhance the strength and longevity of the road surface. Additionally, Bitumen 70/100 has good resistance to water and weathering, ensuring that the asphalt pavement remains intact and functional even in challenging environmental conditions.

In addition to its use in road construction, Bitumen 70/100 is also commonly utilized in waterproofing applications. Its ability to form a waterproof layer when properly applied makes it suitable for sealing roofs, foundations, and other structures to protect them from moisture damage. Furthermore, Bitumen 70/100 can be modified with additives to improve its performance characteristics, such as enhancing its elasticity or reducing its temperature susceptibility, depending on the specific requirements of the project.

Overall, Bitumen 70/100 is a versatile and cost-effective material that plays a crucial role in the construction industry. Its unique properties make it a preferred choice for various applications, from road surfacing to industrial processes. With its excellent adhesion, weather resistance, and versatility, Bitumen 70/100 continues to be a popular choice for engineers, contractors, and manufacturers looking for a reliable and durable construction material.

Bitumen 70/100 Production Process

Bitumen Penetration Grade 70/100, a widely used binder in road construction, is produced through a specific process that involves crude oil refining. The production process generally involves several stages: crude oil distillation, vacuum distillation, and air blowing. Here is a brief overview:

Crude Oil Distillation:

The production of Bitumen 70/100 begins with the distillation of crude oil. Crude oil is heated and then fed into a distillation column, where different components are separated based on their boiling points. The lighter fractions such as gasoline, kerosene, and diesel rise to the top and are siphoned off for other uses. The heavier fractions, known as the bottom residue or atmospheric residue, remain at the bottom and are used to produce bitumen.

Vacuum Distillation:

The atmospheric residue from the previous stage is then subjected to vacuum distillation. Under reduced pressure, heavier components can be distilled off without the need for high temperatures. This further separates the lighter oils from the heavier residue, enhancing the purity of the bitumen precursor. This stage produces a material called vacuum residue or vacuum bottom.

Air Blowing:

Finally, the vacuum residue is processed in a unit known as a ‘bitumen blowing unit’. Here, hot air is blown through the residue under specific conditions of temperature and pressure. This air-blowing process induces chemical reactions that result in increased molecular weight and viscosity of the material, transforming it into bitumen. The blowing process is carefully controlled to produce bitumen with the desired properties – in this case, Bitumen 70/100.

Quality Control:

After the production process, the bitumen undergoes rigorous testing to ensure it meets the required specifications, including penetration and softening point tests to verify that it falls within the 70/100 grade.

The Capability of Bitumen 70/100

Bitumen Grade 70/100 exhibits excellent weather resistance, making it suitable for withstanding varying environmental conditions. Its capacity to endure exposure to elements such as water, sunlight, and temperature fluctuations ensures the longevity and reliability of structures where it is applied. This weather-resistant property, coupled with its adhesive strength, makes Bitumen Grade 70/100 a valuable and dependable material for a wide range of construction applications, from road surfacing to waterproofing and beyond.

Applications of Bitumen 70/100

This kind of bitumen is suitable to be used for road construction projects in moderate climates. Also, it can be used for producing some kind of asphalt primer and Waterproofing products. 70/100 Bitumen

is applicable for the production of hot mix asphalt for bases and pavements and for road construction and also for making some bitumen emulsion, cutback bitumen, and modified bitumen grades as well.

Uses of Bitumen 70/100

Penetration Grade Bitumen 70/100 is a commonly used grade of bitumen in the construction industry and has a wide range of applications. Some of the primary uses of Penetration Grade Bitumen 70/100 include:

- Road construction: Bitumen Penetration Grade 70/100 is used as a binder in asphalt mixtures for road construction. It provides the necessary adhesive properties to hold the aggregate materials together and forms a durable and stable pavement surface.

- Waterproofing: Bitumen Penetration Grade 70/100 is used in the construction of roofing materials, waterproofing membranes, and other protective coatings to provide water resistance and prevent leakage.

- Pavement preservation: Penetration Grade Bitumen 70/100 is also used as a sealant and binder for pavement preservation applications, such as crack sealing and chip sealing, to extend the service life of existing pavements.

- Industrial applications: Penetration Grade Bitumen 70/100 is used in the manufacturing of insulation materials, such as roofing felt and sound insulation products.

- Marine construction: Penetration-grade bitumen 70/100 is used in marine construction as a waterproofing material for seawalls, jetties, and other coastal structures.

- Airport runways: Penetration Grade Bitumen 70/100 is used in the construction of airport runways and taxiways due to its excellent durability and resistance to deformation under heavy traffic loads.

Packing of Bitumen 50/70

Paving Bitumen, Penetration 50/70 is commonly packed in new steel drums, 150, 180 & 220 Kg barrels, and 1MT and 500 kg Jumbo Bags or 300kg Bitubag. Likewise, the rest of the grades are ready to load Ex-work bulk Bitumen by truck.

Kind of Packing for Bitumen 50/70

The Bitumen 50/70 is packed in Different Major:

- Jumbo Bag

- Steel Drums

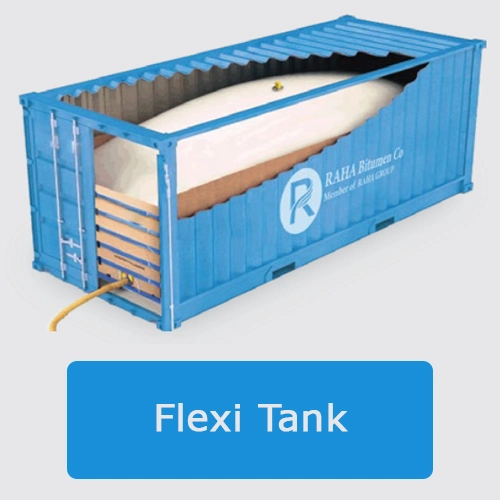

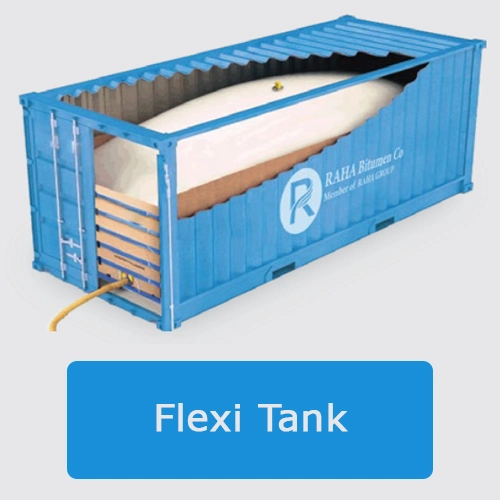

- Flexi Tanks

- Bulk in Trunk Tunker

- Bulk in Bulk Vessel

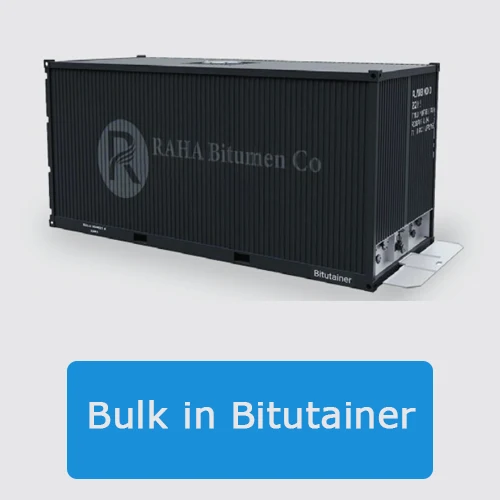

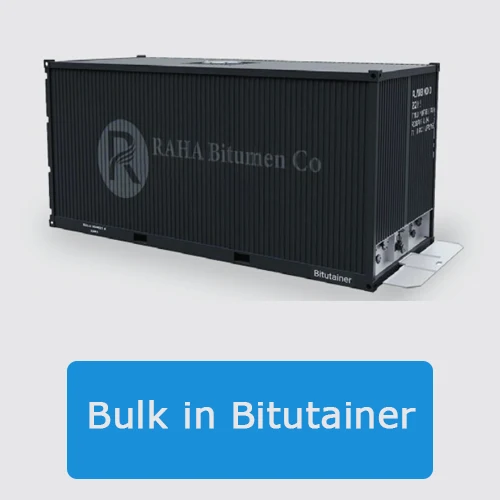

- Bulk in Bitutainer

1. Jumbo Bag

Jumbo bags, also known as Flexible Intermediate Bulk Containers (FIBCs) or big bags, are a popular choice for transporting Bitumen 50/70. These large, flexible bags are typically made from woven polypropylene and are designed to hold between 500 to 2,000 kg of bitumen.

Handling:

- 1MT Jumbo Bag with Pallet and Steel

Cage:

Loading 20Ton in 20ft Container = 20Ton Net

- 1MT Jumbo Bag without Pallet and Steel

Cage:

Loading 20Ton in 40ft Container = 20Ton Net

Advantages of Jumbo Bags in Bitumen 50/70:

- Cost-effective for bulk transportation

- Easy to handle with forklifts or cranes

- Stackable, maximizing storage space

- Reduced risk of contamination

- Suitable for both solid and semi-solid bitumen forms

2. Steel Drums

- 180kg New Steel Drum :

Loading 110 Drum in 20ft Container= 19.80 Ton Net - 150kg New Steel Drum:

Loading 110Drum in 20ft Container= 16.50 Ton Net

Advantages of Steel Drums in Bitumen 50/70:

- Excellent protection against external elements

- Easy to handle and stack

- Suitable for smaller quantity orders

- Reusable or recyclable

- deal for long-term storage

3. Flexi Tanks

Flexi tanks, also known as flexibags or flexitanks, are large, flexible containers designed to fit inside standard 20-foot or 40-foot shipping containers. They are an excellent option for transporting large quantities of liquid or semi-liquid Bitumen 50/70.

Advantages of Flexi Tanks in Bitumen 50/70:

- High capacity (up to 24,000 liters in a 20-foot container)Cost-effective for bulk liquid transportation

- Eliminates the need for drum handling and cleaning

- Maximizes the use of container space

- Reduces packaging waste

4. Bulk in Truck Tanker

- Loading 24-25Ton in Bulk Tanker

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

Specification

| Bitumen 70/100 | Test method | Unit | Specification |

|---|---|---|---|

| Penetration – 25°C, 100g, 5s | EN 1426 | mm | 70-100 |

| Softening Point (Ring & Ball) | EN 1427 | °C | 42/52 |

| Dynamic Viscosity @ 135⁰C | EN 12595 | Pa/s | 0.15-0.4 |

| Solubility in Xylene | EN 12592 | % | 99 Min |

| Flashpoint (Cleveland Open) | EN 22592 | °C | 225 Min |

| Change in mass (m/m) | EN12607-1 | % | 0.8 Max |

| Retained Penetration 25°C, 100g, 5s (% of original) | EN 1426 | % | 46 Min |

| Increase in softening point | EN 1427 | °C | 9 Max |

If you are interested in exporting Bitumen 70/100 to China, please feel free to contact us. Our team specializes in facilitating international trade and ensuring the highest quality standards for bitumen. We are committed to providing seamless service, competitive pricing, and reliable delivery schedules to meet your specific requirements.

Related Posts

Intro

Bitumen 70/100 is a versatile and widely used type of bitumen, often referred to as asphalt binder, renowned for its balance of flexibility and durability. It falls within the penetration grade bitumens, classified based on the depth (measured in tenths of a millimeter) a standard needle penetrates the bitumen sample under specific conditions. The 70/100 designation signifies that the needle penetrates between 70 and 100 units, indicating a medium-hard consistency. This makes Bitumen 70/100 particularly suitable for a range of climatic conditions and various types of road construction and maintenance.

Bitumen 70/100 is also appreciated for its workability during the construction process. Its medium penetration grade ensures that it can be easily mixed and applied, while still providing a strong, cohesive bond once it sets. This makes it a favorite among contractors and engineers who seek efficiency and reliability in their paving materials. Additionally, the bitumen can be modified with polymers or other additives to enhance certain properties, such as elasticity or resistance to deformation, further broadening its application scope.

General Description of Bitumen 70/100

Bitumen 70/100, also known as penetration-grade bitumen, is a widely used construction material known for its versatility and durability. It is a type of bitumen that falls within a specific range of penetration values, indicating its consistency and softness. Bitumen 70/100 has a penetration value of 70 to 100 dmm (0.1 mm) at 25 degrees Celsius, which makes it suitable for a variety of applications in road construction, waterproofing, and industrial processes.

One of the key characteristics of Bitumen 70/100 is its excellent adhesive properties, which allow it to effectively bind various aggregates together to form durable asphalt mixtures. This makes it an ideal choice for use in asphalt pavements, where it helps enhance the strength and longevity of the road surface. Additionally, Bitumen 70/100 has good resistance to water and weathering, ensuring that the asphalt pavement remains intact and functional even in challenging environmental conditions.

In addition to its use in road construction, Bitumen 70/100 is also commonly utilized in waterproofing applications. Its ability to form a waterproof layer when properly applied makes it suitable for sealing roofs, foundations, and other structures to protect them from moisture damage. Furthermore, Bitumen 70/100 can be modified with additives to improve its performance characteristics, such as enhancing its elasticity or reducing its temperature susceptibility, depending on the specific requirements of the project.

Overall, Bitumen 70/100 is a versatile and cost-effective material that plays a crucial role in the construction industry. Its unique properties make it a preferred choice for various applications, from road surfacing to industrial processes. With its excellent adhesion, weather resistance, and versatility, Bitumen 70/100 continues to be a popular choice for engineers, contractors, and manufacturers looking for a reliable and durable construction material.

Bitumen 70/100 Production Process

Bitumen Penetration Grade 70/100, a widely used binder in road construction, is produced through a specific process that involves crude oil refining. The production process generally involves several stages: crude oil distillation, vacuum distillation, and air blowing. Here is a brief overview:

Crude Oil Distillation:

The production of Bitumen 70/100 begins with the distillation of crude oil. Crude oil is heated and then fed into a distillation column, where different components are separated based on their boiling points. The lighter fractions such as gasoline, kerosene, and diesel rise to the top and are siphoned off for other uses. The heavier fractions, known as the bottom residue or atmospheric residue, remain at the bottom and are used to produce bitumen.

Vacuum Distillation:

The atmospheric residue from the previous stage is then subjected to vacuum distillation. Under reduced pressure, heavier components can be distilled off without the need for high temperatures. This further separates the lighter oils from the heavier residue, enhancing the purity of the bitumen precursor. This stage produces a material called vacuum residue or vacuum bottom.

Air Blowing:

Finally, the vacuum residue is processed in a unit known as a ‘bitumen blowing unit’. Here, hot air is blown through the residue under specific conditions of temperature and pressure. This air-blowing process induces chemical reactions that result in increased molecular weight and viscosity of the material, transforming it into bitumen. The blowing process is carefully controlled to produce bitumen with the desired properties – in this case, Bitumen 70/100.

Quality Control:

After the production process, the bitumen undergoes rigorous testing to ensure it meets the required specifications, including penetration and softening point tests to verify that it falls within the 70/100 grade.

The Capability of Bitumen 70/100

Bitumen Grade 70/100 exhibits excellent weather resistance, making it suitable for withstanding varying environmental conditions. Its capacity to endure exposure to elements such as water, sunlight, and temperature fluctuations ensures the longevity and reliability of structures where it is applied. This weather-resistant property, coupled with its adhesive strength, makes Bitumen Grade 70/100 a valuable and dependable material for a wide range of construction applications, from road surfacing to waterproofing and beyond.

Applications of Bitumen 70/100

This kind of bitumen is suitable to be used for road construction projects in moderate climates. Also, it can be used for producing some kind of asphalt primer and Waterproofing products. 70/100 Bitumen

is applicable for the production of hot mix asphalt for bases and pavements and for road construction and also for making some bitumen emulsion, cutback bitumen, and modified bitumen grades as well.

Uses of Bitumen 70/100

Penetration Grade Bitumen 70/100 is a commonly used grade of bitumen in the construction industry and has a wide range of applications. Some of the primary uses of Penetration Grade Bitumen 70/100 include:

- Road construction: Bitumen Penetration Grade 70/100 is used as a binder in asphalt mixtures for road construction. It provides the necessary adhesive properties to hold the aggregate materials together and forms a durable and stable pavement surface.

- Waterproofing: Bitumen Penetration Grade 70/100 is used in the construction of roofing materials, waterproofing membranes, and other protective coatings to provide water resistance and prevent leakage.

- Pavement preservation: Penetration Grade Bitumen 70/100 is also used as a sealant and binder for pavement preservation applications, such as crack sealing and chip sealing, to extend the service life of existing pavements.

- Industrial applications: Penetration Grade Bitumen 70/100 is used in the manufacturing of insulation materials, such as roofing felt and sound insulation products.

- Marine construction: Penetration-grade bitumen 70/100 is used in marine construction as a waterproofing material for seawalls, jetties, and other coastal structures.

- Airport runways: Penetration Grade Bitumen 70/100 is used in the construction of airport runways and taxiways due to its excellent durability and resistance to deformation under heavy traffic loads.

Packing of Bitumen 50/70

Paving Bitumen, Penetration 50/70 is commonly packed in new steel drums, 150, 180 & 220 Kg barrels, and 1MT and 500 kg Jumbo Bags or 300kg Bitubag. Likewise, the rest of the grades are ready to load Ex-work bulk Bitumen by truck.

Kind of Packing for Bitumen 50/70

The Bitumen 50/70 is packed in Different Major:

- Jumbo Bag

- Steel Drums

- Flexi Tanks

- Bulk in Trunk Tunker

- Bulk in Bulk Vessel

- Bulk in Bitutainer

1. Jumbo Bag

Jumbo bags, also known as Flexible Intermediate Bulk Containers (FIBCs) or big bags, are a popular choice for transporting Bitumen 50/70. These large, flexible bags are typically made from woven polypropylene and are designed to hold between 500 to 2,000 kg of bitumen.

Handling:

- 1MT Jumbo Bag with Pallet and Steel

Cage:

Loading 20Ton in 20ft Container = 20Ton Net

- 1MT Jumbo Bag without Pallet and Steel

Cage:

Loading 20Ton in 40ft Container = 20Ton Net

Advantages of Jumbo Bags in Bitumen 50/70:

- Cost-effective for bulk transportation

- Easy to handle with forklifts or cranes

- Stackable, maximizing storage space

- Reduced risk of contamination

- Suitable for both solid and semi-solid bitumen forms

2. Steel Drums

- 180kg New Steel Drum :

Loading 110 Drum in 20ft Container= 19.80 Ton Net - 150kg New Steel Drum:

Loading 110Drum in 20ft Container= 16.50 Ton Net

Advantages of Steel Drums in Bitumen 50/70:

- Excellent protection against external elements

- Easy to handle and stack

- Suitable for smaller quantity orders

- Reusable or recyclable

- deal for long-term storage

3. Flexi Tanks

Flexi tanks, also known as flexibags or flexitanks, are large, flexible containers designed to fit inside standard 20-foot or 40-foot shipping containers. They are an excellent option for transporting large quantities of liquid or semi-liquid Bitumen 50/70.

Advantages of Flexi Tanks in Bitumen 50/70:

- High capacity (up to 24,000 liters in a 20-foot container)Cost-effective for bulk liquid transportation

- Eliminates the need for drum handling and cleaning

- Maximizes the use of container space

- Reduces packaging waste

4. Bulk in Truck Tanker

- Loading 24-25Ton in Bulk Tanker

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

5. Bulk in Bulk Vessel

- Loading 1,000-30,000 Ton in Bitumen

Carrier Vessel

6. Bulk in Bitutainer

- Loading 25 Ton in Bitutainer

Specification

| Bitumen 70/100 | Test method | Unit | Specification |

|---|---|---|---|

| Penetration – 25°C, 100g, 5s | EN 1426 | mm | 70-100 |

| Softening Point (Ring & Ball) | EN 1427 | °C | 42/52 |

| Dynamic Viscosity @ 135⁰C | EN 12595 | Pa/s | 0.15-0.4 |

| Solubility in Xylene | EN 12592 | % | 99 Min |

| Flashpoint (Cleveland Open) | EN 22592 | °C | 225 Min |

| Change in mass (m/m) | EN12607-1 | % | 0.8 Max |

| Retained Penetration 25°C, 100g, 5s (% of original) | EN 1426 | % | 46 Min |

| Increase in softening point | EN 1427 | °C | 9 Max |

If you are interested in exporting Bitumen 70/100 to China, please feel free to contact us. Our team specializes in facilitating international trade and ensuring the highest quality standards for bitumen. We are committed to providing seamless service, competitive pricing, and reliable delivery schedules to meet your specific requirements.