Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for paving roads and roofing. Its unique properties of adhesiveness, waterproofing, and durability make it indispensable in creating long-lasting surfaces that withstand environmental and mechanical stress. Beyond construction, bitumen also finds applications in industrial products like adhesives and sealants, showcasing its versatility and economic significance.

Definition of Bitumen Penetration

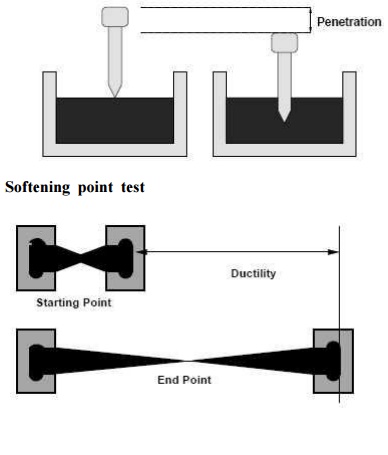

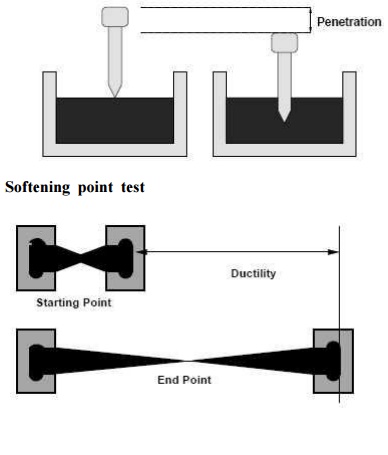

Bitumen Penetration Grade is a semi-hard black refinery bitumen that is produced in different viscosities and is known as petroleum bitumen. To determine the hardness of bitumen, a penetration test is performed. That’s why this bitumen is called infiltration. In addition to the penetration test, the soft point test is also used. The main assumption of penetration grading is that the more viscous the asphalt, the deeper the needle penetrates. Bitumen penetration grades range from 15 to 450 for road bitumen. But the most commonly used range is 25 to 200. This is achieved by controlling the experiment performed i.e. the distillation process. Partial control of residual bitumen flux with oils can contribute to the required hardness.

Penetration grade bitumen is a standard bitumen that is commonly used as a pavement grade bitumen essential for road construction and producing asphalt pavements with superior properties when it binds the aggregates and provides unique cohesion and stability to the bituminous mixture. Slow is very important.

Penetration-grade bitumen has thermoplastic properties that make the material soft at high temperatures and hard at low temperatures. This unique temperature/viscosity relationship is important when determining performance parameters such as adhesion, rheology, durability, and bitumen application temperature.

The penetration of bituminous materials is its consistency, which is expressed as the distance that a standard needle penetrates vertically into a sample of the material under certain conditions of temperature, load, and duration of loading, expressed in tenths of millimeters.

History of Bitumen

The use of bitumen dates back to ancient civilizations. The Mesopotamians used natural bitumen as a waterproofing agent for constructing buildings and boats. The Egyptians employed it in the mummification process and for sealing baths and cisterns. Over the centuries, the methods of bitumen extraction and application have evolved significantly. The advent of the Industrial Revolution and advancements in refining techniques have allowed for more efficient production and varied uses. Today, bitumen is a cornerstone material in modern infrastructure, highlighting its enduring significance.

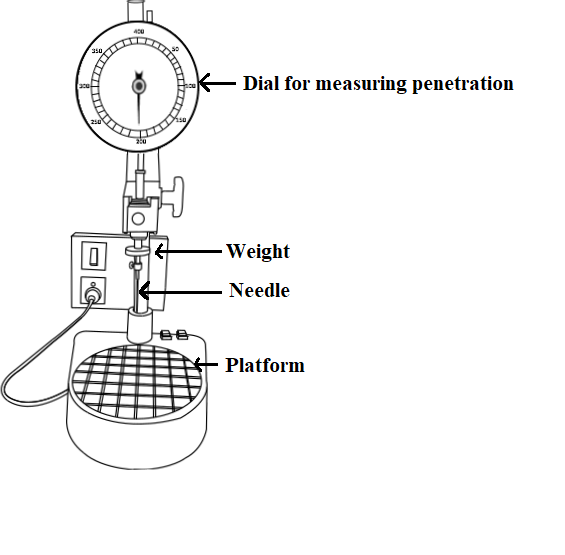

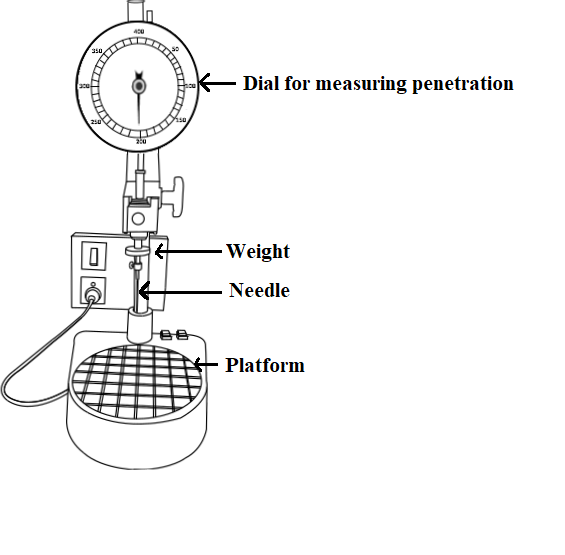

Components for the penetration test

- Water bath: it contains at least 10 liters of water at a temperature of 25 °C. The sample is immersed in a depth of more than 100 mm from the top. Moreover, the supported perforated shelf which is the sample being placed on it should be above 50mm from the bottom of the bath. Sample container: a small cylindrical dish with a flat bottom, which its material is metal or glass.

- Transfer dish or Tray: It helps in keeping the container immersed in the water bath.

- Penetration needle: stainless steel needle which is cylindrical and highly polished.

- Stopwatch: an automatic timer with an accuracy of 1/10 seconds.

- Thermometer: it shows the temperature in the range of 0-44 °C.

- Penetrometer: the device contains a needle. It is used to release and lock the needle in any position and allows measuring the penetration by applying a load of 100 grams with the least friction. It is important to calibrate accurately.

Steps to Bitumen Penetration Test:

- A sample of bitumen must be prepared primarily. For the sample, bitumen can be taken from a bulk source or a bitumen tank container. The sample must accurately represent the material being tested.

- The collected bitumen sample is then conditioned to a specific temperature, typically between 25-30 degrees Celsius. This is done to eliminate temperature-related variations.

- To conduct the test, we need a few apparatus like a penetrometer, a needle and a test container. The conditioned bitumen sample should be filled in the test container and leveled.

- A stainless steel needle is carefully positioned vertically above the bitumen sample. Then, a specific weight is applied to the needle.

- The needle is then allowed to penetrate the bitumen sample for a specific time duration.

- After the defined time, depth to which the needle has penetrated the sample is measured in tenths of a millimeter or hundredths of an inch. This measurement is known as the penetration value.

- The test is repeated multiple times with fresh samples to ensure accuracy and consistency. Final result would be the average of multiple penetration values reported.

Application of Bitumen Penetration

Bitumen with different penetration grades finds diverse applications across various fields, primarily in the construction and infrastructure sectors. The penetration grade of bitumen is determined by its consistency and hardness, as assessed through penetration testing. Different penetration grades are suitable for different applications based on the specific requirements of each field.

- Road Construction

- Roofing and Waterproofing

- Pavement Preservation

- Road Construction

penetration grade is a common type of bitumen used in road construction due to its desirable properties. It is classified based on its penetration value, which indicates the hardness of the bitumen.

Asphalt Binders:

• Asphalt penetration grade is widely used as a binder in asphalt mixes for road construction. It provides the necessary adhesive properties to bind aggregates, creating a durable and flexible road surface. - Pavement Construction:

• Penetration-grade bitumen is used to construct various pavement layers, including the base and wearing courses. It helps to create a stable and resilient pavement structure capable of withstanding traffic loads and environmental conditions. - Flexible Pavements:

• penetration grade is a crucial component in the construction of flexible pavements, where the asphalt layers are designed to deform under traffic loads and then recover their original shape. This flexibility helps to distribute the load and reduce stresses on the underlying layers. - Waterproofing:

• penetration grade is used for waterproofing applications in road construction. It is applied to various surfaces to prevent water infiltration and protect the underlying layers from damage caused by moisture. - Crack Sealing and Repair:

• Penetration grade can be used for crack sealing and repair work on existing road surfaces. It helps to fill and seal cracks, preventing the intrusion of water and minimizing further damage to the pavement. - Adhesion Properties:

• The adhesive properties of penetration grade are crucial for ensuring proper bonding between asphalt layers and between the asphalt and the aggregate. This adhesion contributes to the overall strength and stability of the road. - Temperature Susceptibility:

• Bitumen penetration grade is selected based on the local climate and temperature conditions. The choice of penetration grade ensures that the bitumen remains flexible and workable within the temperature range experienced in a particular region. - Resistance to Rutting and Deformation:

• The use of appropriate bitumen penetration grade helps in enhancing the resistance of the asphalt pavement to rutting and deformation, particularly in areas with high traffic volumes and heavy loads.

penetration grade is a versatile material that plays a crucial role in various aspects of road construction, contributing to the durability, flexibility, and overall performance of asphalt pavements. The selection of the appropriate penetration grade depends on factors such as climate, traffic conditions, and the specific requirements of the road project.

Recommended: Bitumen 60/70, also known as asphalt 60/70, is a sustainable material used to manufacture hot mix asphalt for foundations, pavements, and road construction: Bitumen Penetration 60/70

Bitumen Penetration safety tips

- a good understanding of their chemical and physical properties;

- proper procedures and safe systems of work;

- effective safety equipment and protective clothing;

- full, conscientious training of all people involved. Other relevant aspects include storage tank considerations, pipework layout, general housekeeping, control and instrumentation, access, and delivery.

The Institute of Petroleum Bitumen Safety Code is comprehensive and highly recommended. Concern with safety and hazards is essential for moral, legal, and economic reasons. The potential hazards of bitumen are that it is hot, occasionally with temperatures exceeding 250 degrees C, that it emits fumes when heated, that it is inflammable and can explode, and that it can foam in the presence of water.

Although bitumen emulsions are handled at lower temperatures, normally about 85 degrees C, they must still be treated with care. Protective clothing should be enough to avoid personal injury and includes overalls, gloves, and full head and face protection.

All bitumen burns should be treated as soon as possible by a medical professional, after suitable first aid. Vehicles conveying bitumen should be designed, built, and maintained to the highest standards. Training of all people handling bitumen is a top priority.

Bitumen Penetration Grade

| ASTMD946-09 | EN12591-2009 |

|---|---|

| Bitumen 10/20 | Bitumen 20/30 |

| Bitumen 30/40 | Bitumen 30/45 |

| Bitumen 40/50 | Bitumen 35/50 |

| Bitumen 60/70 | Bitumen 40/60 |

| Bitumen 80/100 | Bitumen 50/70 |

| Bitumen 85/100 | Bitumen 70/100 |

| Bitumen 120/150 | Bitumen 100/150 |

| Bitumen 200/300 | Bitumen 160/220 |

ASTMD946-09 Grades

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

ASTMD946-09 Grades

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

If you are interested in exporting Each Grade of Bitumen Penetration to China, please feel free to contact us. Our team specializes in facilitating international trade and ensuring the highest quality standards for bitumen. We are committed to providing seamless service, competitive pricing, and reliable delivery schedules to meet your specific requirements.

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for paving roads and roofing. Its unique properties of adhesiveness, waterproofing, and durability make it indispensable in creating long-lasting surfaces that withstand environmental and mechanical stress. Beyond construction, bitumen also finds applications in industrial products like adhesives and sealants, showcasing its versatility and economic significance.

Definition of Bitumen Penetration

Bitumen Penetration Grade is a semi-hard black refinery bitumen that is produced in different viscosities and is known as petroleum bitumen. To determine the hardness of bitumen, a penetration test is performed. That’s why this bitumen is called infiltration. In addition to the penetration test, the soft point test is also used. The main assumption of penetration grading is that the more viscous the asphalt, the deeper the needle penetrates. Bitumen penetration grades range from 15 to 450 for road bitumen. But the most commonly used range is 25 to 200. This is achieved by controlling the experiment performed i.e. the distillation process. Partial control of residual bitumen flux with oils can contribute to the required hardness.

Penetration grade bitumen is a standard bitumen that is commonly used as a pavement grade bitumen essential for road construction and producing asphalt pavements with superior properties when it binds the aggregates and provides unique cohesion and stability to the bituminous mixture. Slow is very important.

Penetration-grade bitumen has thermoplastic properties that make the material soft at high temperatures and hard at low temperatures. This unique temperature/viscosity relationship is important when determining performance parameters such as adhesion, rheology, durability, and bitumen application temperature.

The penetration of bituminous materials is its consistency, which is expressed as the distance that a standard needle penetrates vertically into a sample of the material under certain conditions of temperature, load, and duration of loading, expressed in tenths of millimeters.

History of Bitumen

The use of bitumen dates back to ancient civilizations. The Mesopotamians used natural bitumen as a waterproofing agent for constructing buildings and boats. The Egyptians employed it in the mummification process and for sealing baths and cisterns. Over the centuries, the methods of bitumen extraction and application have evolved significantly. The advent of the Industrial Revolution and advancements in refining techniques have allowed for more efficient production and varied uses. Today, bitumen is a cornerstone material in modern infrastructure, highlighting its enduring significance.

Components for the penetration test

- Water bath: it contains at least 10 liters of water at a temperature of 25 °C. The sample is immersed in a depth of more than 100 mm from the top. Moreover, the supported perforated shelf which is the sample being placed on it should be above 50mm from the bottom of the bath. Sample container: a small cylindrical dish with a flat bottom, which its material is metal or glass.

- Transfer dish or Tray: It helps in keeping the container immersed in the water bath.

- Penetration needle: stainless steel needle which is cylindrical and highly polished.

- Stopwatch: an automatic timer with an accuracy of 1/10 seconds.

- Thermometer: it shows the temperature in the range of 0-44 °C.

- Penetrometer: the device contains a needle. It is used to release and lock the needle in any position and allows measuring the penetration by applying a load of 100 grams with the least friction. It is important to calibrate accurately.

Steps to Bitumen Penetration Test:

- A sample of bitumen must be prepared primarily. For the sample, bitumen can be taken from a bulk source or a bitumen tank container. The sample must accurately represent the material being tested.

- The collected bitumen sample is then conditioned to a specific temperature, typically between 25-30 degrees Celsius. This is done to eliminate temperature-related variations.

- To conduct the test, we need a few apparatus like a penetrometer, a needle and a test container. The conditioned bitumen sample should be filled in the test container and leveled.

- A stainless steel needle is carefully positioned vertically above the bitumen sample. Then, a specific weight is applied to the needle.

- The needle is then allowed to penetrate the bitumen sample for a specific time duration.

- After the defined time, depth to which the needle has penetrated the sample is measured in tenths of a millimeter or hundredths of an inch. This measurement is known as the penetration value.

- The test is repeated multiple times with fresh samples to ensure accuracy and consistency. Final result would be the average of multiple penetration values reported.

Application of Bitumen Penetration

Bitumen with different penetration grades finds diverse applications across various fields, primarily in the construction and infrastructure sectors. The penetration grade of bitumen is determined by its consistency and hardness, as assessed through penetration testing. Different penetration grades are suitable for different applications based on the specific requirements of each field.

- Road Construction

- Roofing and Waterproofing

- Pavement Preservation

- Road Construction

penetration grade is a common type of bitumen used in road construction due to its desirable properties. It is classified based on its penetration value, which indicates the hardness of the bitumen.

Asphalt Binders:

• Asphalt penetration grade is widely used as a binder in asphalt mixes for road construction. It provides the necessary adhesive properties to bind aggregates, creating a durable and flexible road surface. - Pavement Construction:

• Penetration-grade bitumen is used to construct various pavement layers, including the base and wearing courses. It helps to create a stable and resilient pavement structure capable of withstanding traffic loads and environmental conditions. - Flexible Pavements:

• penetration grade is a crucial component in the construction of flexible pavements, where the asphalt layers are designed to deform under traffic loads and then recover their original shape. This flexibility helps to distribute the load and reduce stresses on the underlying layers. - Waterproofing:

• penetration grade is used for waterproofing applications in road construction. It is applied to various surfaces to prevent water infiltration and protect the underlying layers from damage caused by moisture. - Crack Sealing and Repair:

• Penetration grade can be used for crack sealing and repair work on existing road surfaces. It helps to fill and seal cracks, preventing the intrusion of water and minimizing further damage to the pavement. - Adhesion Properties:

• The adhesive properties of penetration grade are crucial for ensuring proper bonding between asphalt layers and between the asphalt and the aggregate. This adhesion contributes to the overall strength and stability of the road. - Temperature Susceptibility:

• Bitumen penetration grade is selected based on the local climate and temperature conditions. The choice of penetration grade ensures that the bitumen remains flexible and workable within the temperature range experienced in a particular region. - Resistance to Rutting and Deformation:

• The use of appropriate bitumen penetration grade helps in enhancing the resistance of the asphalt pavement to rutting and deformation, particularly in areas with high traffic volumes and heavy loads.

penetration grade is a versatile material that plays a crucial role in various aspects of road construction, contributing to the durability, flexibility, and overall performance of asphalt pavements. The selection of the appropriate penetration grade depends on factors such as climate, traffic conditions, and the specific requirements of the road project.

Recommended: Bitumen 60/70, also known as asphalt 60/70, is a sustainable material used to manufacture hot mix asphalt for foundations, pavements, and road construction: Bitumen Penetration 60/70

Bitumen Penetration safety tips

- a good understanding of their chemical and physical properties;

- proper procedures and safe systems of work;

- effective safety equipment and protective clothing;

- full, conscientious training of all people involved. Other relevant aspects include storage tank considerations, pipework layout, general housekeeping, control and instrumentation, access, and delivery.

The Institute of Petroleum Bitumen Safety Code is comprehensive and highly recommended. Concern with safety and hazards is essential for moral, legal, and economic reasons. The potential hazards of bitumen are that it is hot, occasionally with temperatures exceeding 250 degrees C, that it emits fumes when heated, that it is inflammable and can explode, and that it can foam in the presence of water.

Although bitumen emulsions are handled at lower temperatures, normally about 85 degrees C, they must still be treated with care. Protective clothing should be enough to avoid personal injury and includes overalls, gloves, and full head and face protection.

All bitumen burns should be treated as soon as possible by a medical professional, after suitable first aid. Vehicles conveying bitumen should be designed, built, and maintained to the highest standards. Training of all people handling bitumen is a top priority.

Bitumen Penetration Grade

| ASTMD946-09 | EN12591-2009 |

|---|---|

| Bitumen 10/20 | Bitumen 20/30 |

| Bitumen 30/40 | Bitumen 30/45 |

| Bitumen 40/50 | Bitumen 35/50 |

| Bitumen 60/70 | Bitumen 40/60 |

| Bitumen 80/100 | Bitumen 50/70 |

| Bitumen 85/100 | Bitumen 70/100 |

| Bitumen 120/150 | Bitumen 100/150 |

| Bitumen 200/300 | Bitumen 160/220 |

ASTMD946-09 Grades

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

ASTMD946-09 Grades

Bitumen 85/100

AT RAHA Bitumen Co, We are Exporter and Supplier of Bitumen 85/100 to East Asia and Africa. For more information about price, [...]

Bitumen 30/40

At RAHA Bitumen, We are Manufacturer and Supplier of different grades of Bitumen such as Bitumen 30/40 . We have over 13 years [...]

Supplier of Hard Grade Bitumen 10/20 to East Asia and Africa

Intro Bitumen 10/20 is a crucial component in the world of construction and infrastructure development, playing a vital role in creating [...]

Understanding Bitumen Penetration

Bitumen Penetration, also known as asphalt, is a fundamental material in the construction and infrastructure sectors, primarily used for [...]

Bitumen 60/70 in China

Bitumen 60/70 in China is a popular Grade and widely used in Construction and repair and it has a special packing [...]

If you are interested in exporting Each Grade of Bitumen Penetration to China, please feel free to contact us. Our team specializes in facilitating international trade and ensuring the highest quality standards for bitumen. We are committed to providing seamless service, competitive pricing, and reliable delivery schedules to meet your specific requirements.